Introduction of Electroplating

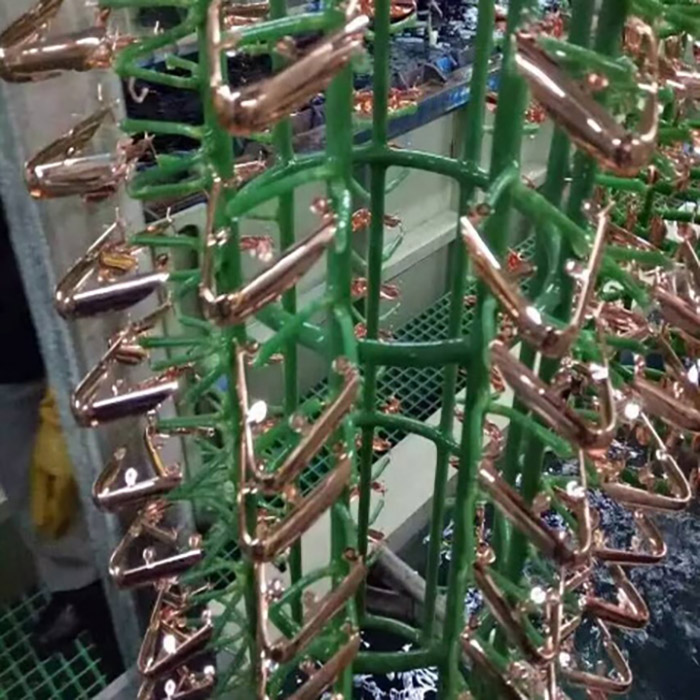

Electroplating is a process in which a metal coating is deposited onto the surface of an iron product using an electric current. The process involves immersing the iron product in an electrolyte solution containing metal ions of the desired coating material. The iron product is then connected to the negative terminal of a power source, while a metal anode of the desired coating material is connected to the positive terminal. When an electric current is passed through the solution, metal ions from the anode are attracted to the iron product, where they are reduced and deposited as a thin layer of metal coating. There will be 3 kinds of metal coating on the iron surface. 1. copper, 2. nickel, 3. chrome. After the metal coating, it will be spray a transparent resin on the surface to protect the metal coating.

The electroplating process offers several advantages, including

1. Enhanced corrosion resistance The metal coating provides a barrier against corrosion, protecting the iron product from rust and other forms of corrosion.

2. Improved aesthetics The metal coating can improve the appearance of the iron product, making it more attractive and appealing.

3. Increased durability The metal coating can improve the durability and strength of the iron product, making it more resistant to wear and tear.